Our SAS 3.0/4.0 series connectors deliver exceptional data transfer speeds of up to 24 Gb/s, ensuring stable and efficient transmission for enterprise storage and server systems. Designed with high reliability and hot-plug capability, each connector undergoes strict quality control and automated precision manufacturing. With flexible customization options and strong R&D support, our SAS connectors are ideal for both board-to-board and wire-to-board applications in enterprise storage systems, servers, and data centers requiring consistent, high-speed performance. ShuangYi Precision — Powering Smarter Connections.

ShuangYi Precision — Powering Smarter Connections.

Why Choose Us:

• Free samples available for quality evaluation.

• Support for both OEM & ODM customization.

• Trade Terms: EXW, FOB, CIF, CPT, etc.

Notice: The displayed price is only for reference. Contact us now for the best offer and detailed quotation!

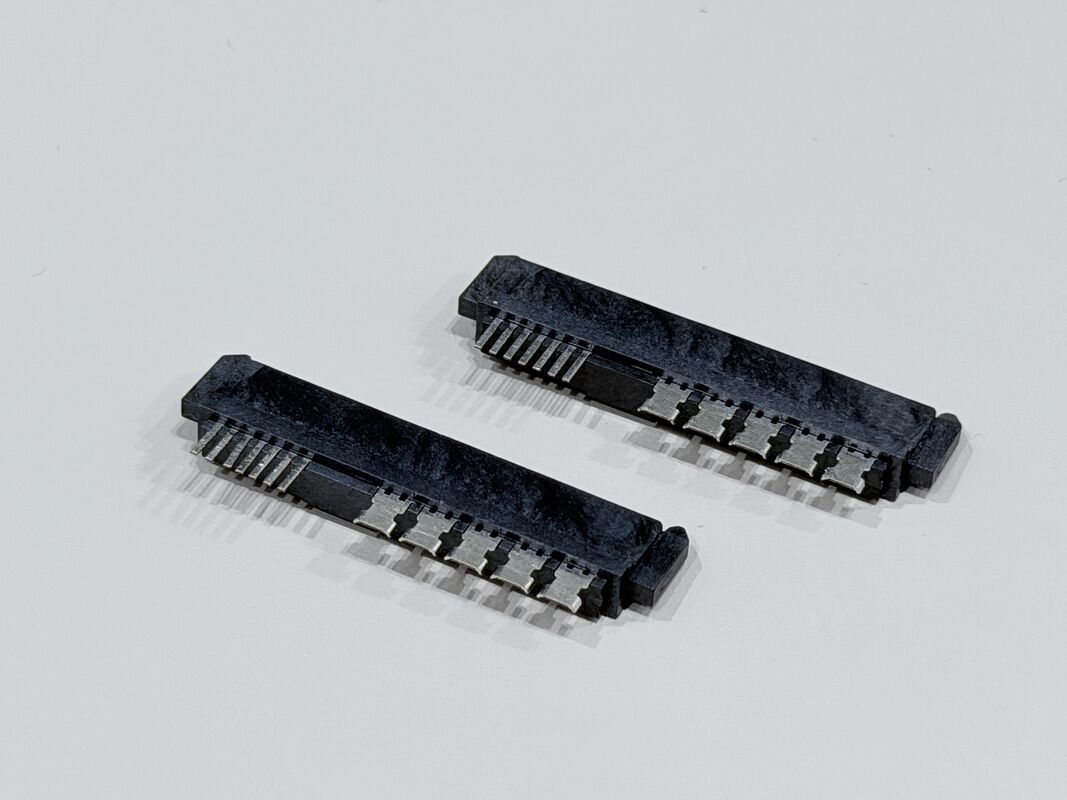

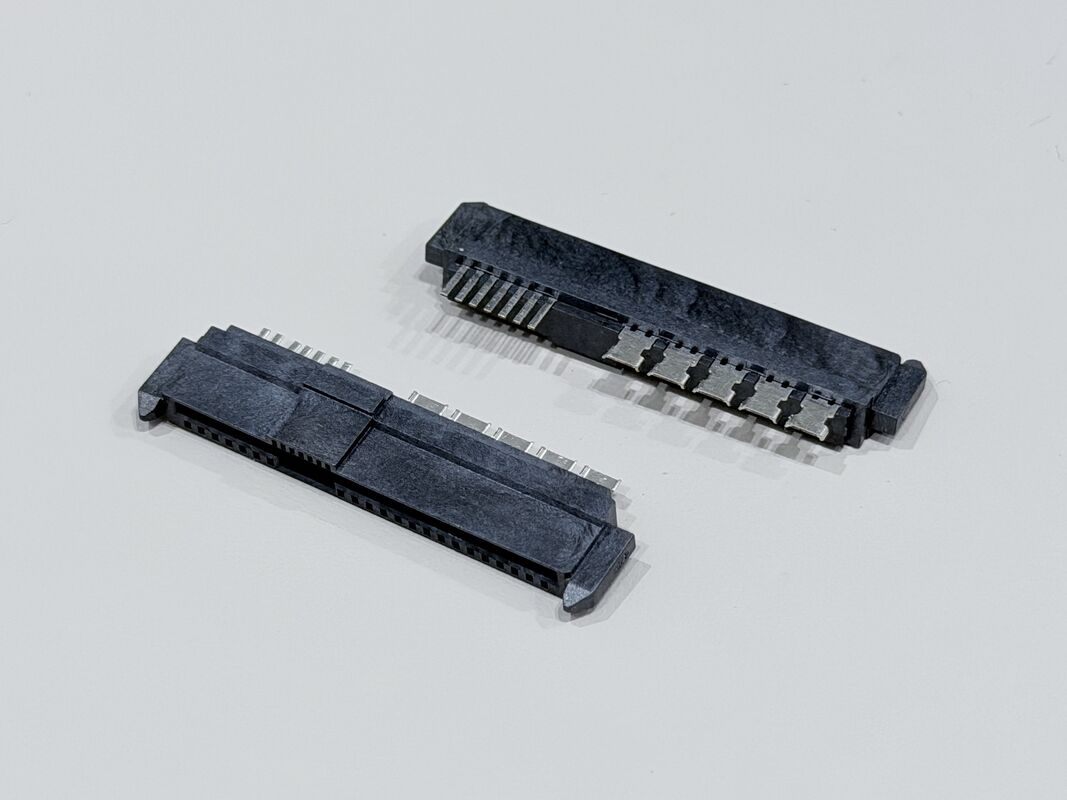

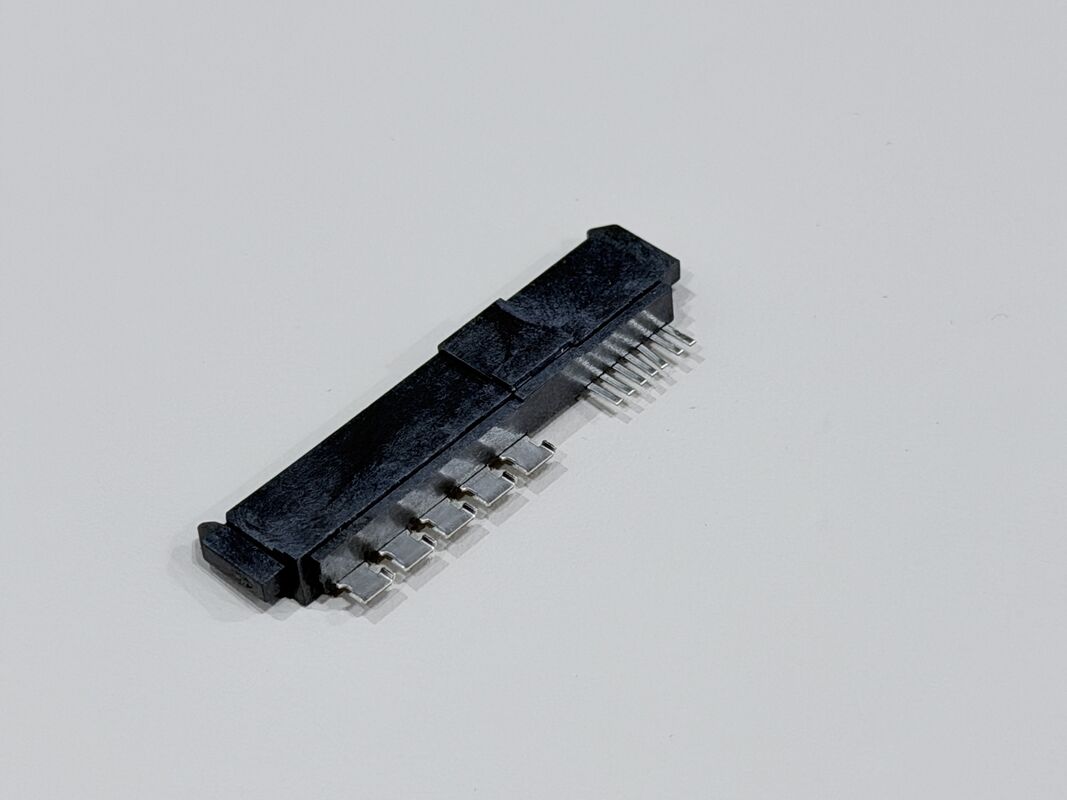

The SAS 29P dummy female connector is a 1.27mm pitch electronic connector designed for test, simulation and protection of SAS / SATA interfaces in servers, storage systems and industrial equipment. It uses a 180° solder wire termination, allowing wires or cables to be soldered directly to the terminals, making it suitable for customized electrical and electronic wire harnesses where a dummy or simulated SAS 29-pin interface is required.

Terminals are made from phosphor bronze C5191-H (t = 0.25mm) and finished with a robust plating system: 50µ" nickel underlayer for corrosion resistance, 15µ" gold on the contact area to keep low and stable contact resistance, and 80µ" tin on the solder and crimp area to ensure reliable solder joints to the wire. The housing and base are molded from glass-filled LCP, black, UL94-V0, providing high mechanical strength, dimensional stability and heat resistance during soldering.

With a rating of 1.5A @ 40VAC, contact resistance ≤30mΩ, insulation resistance ≥1000MΩ and dielectric strength of 500VAC/minute, this 29-pin dummy female connector offers stable performance for both signal and low-power transmission. The defined mating, unmating and pin retention forces help maintain secure engagement with the mating plug and prevent accidental disconnection, making it a reliable choice for PCB, wire and cable customization in server, automotive, transmission and other power-electronic applications.

| Product Type |

SAS dummy 29P straight female connector, 180° solder wire type, without boss and without small YP |

| Interface Series |

SATA / SAS series (dummy 29-pin female) |

| Number of Positions |

29 pins (dummy female layout) |

| Pitch of Housing |

1.27mm |

| Gender |

Female connector |

| Termination Style |

S38: Solder way of 180° terminal with wire (solder wire type) |

| Rated Current / Voltage |

1.5A @ 40VAC |

| Operating Temperature |

–20°C to +85°C |

| Contact Resistance |

≤ 30mΩ (Max) |

| Insulation Resistance |

≥ 1000MΩ (Min) |

| Withstand Voltage |

500VAC / minute |

| Single Pin Retention Force |

≥ 0.8kgf per pin |

| Mating Force |

≤ 4.5kgf max (test speed 25mm/min) |

| Unmating Force |

≥ 0.51kgf min (test speed 25mm/min) |

| Terminal Plating – Underlayer |

Ni 50µ" min plated over terminal |

| Terminal Plating – Contact Area |

Au 15µ" plated on contact area |

| Terminal Plating – Solder/Crimp Area |

Sn 80µ" min plated on solder & crimp area |

| Terminal Material |

Phosphor Bronze C5191-H, t = 0.25mm (TS-C15F-S83 / TS-C07F-S37) |

| Housing Material |

LCP G/F Black UL94-V0 (HSS-C29F-029) |

| Base Material |

LCP G/F Black UL94-V0 (BSS-C29F-025) |

| Environmental Compliance |

RoHS 2.0 compliant |

| Typical Connection |

Wire-to-connector for dummy SAS/SATA interface, signal simulation and power connection in electrical / electronic systems |

Key Features

- True SAS 29P female connector with 1.27mm pitch for high-density PCB layouts

- Right-angle (R90°) solder wire design optimizes cable routing in slim server and industrial enclosures

- Ni 50U" + Au 15U" + Sn 80U" plating for excellent conductivity, low contact resistance and long-term corrosion resistance

- Phosphor bronze C5191-H terminals provide stable contact force and durability under vibration and thermal cycling

- LCP G/F UL94-V0 HF housing ensures high mechanical strength and heat resistance for demanding electronic environments

- Positioning peg and thick back cover enhance assembly accuracy, cable strain relief and mechanical stability

- Defined mating / unmating forces and single-pin retention ≥0.8kgf guarantee secure, reliable connections in wiring harnesses

- Suitable for electrical power and electronic signal transmission, compatible with customization for different wire gauges and cable types

⚙️ Applications

- Server & Data Center Equipment – Used as SAS / SATA electronic signal and power connectors on HDD/SSD backplanes, RAID cards, JBOD/NAS and 1U/2U server boards.

- Communication & Networking Systems – For routers, switches, base stations and other networking equipment that need compact PCB connectors and reliable high-speed transmission.

- Industrial & Automation Electronics – Applied in industrial PCs, PLCs, motion controllers, data loggers and test instruments as PCB-to-wire or cable connectors.

- Automotive & New Energy Applications – Used in in-vehicle data recorders, infotainment units, EV chargers and energy-storage systems for signal and low-power transmission.

- Custom Wire Harness & Cable Assemblies – Suitable for OEM/ODM projects that require connector customization for PCB, wire and cable layouts in electrical and electronic devices.

⚠️ Notes

- Make sure the working voltage, current and temperature of your design stay within the connector’s rated values, with proper safety margin.

- Design PCB pads, holes and mechanical space according to the drawing and pitch, and avoid bending or twisting stress on the connector after soldering or assembly.

- Select appropriate wire gauge, insulation and cable structure based on current load, signal speed and bending requirements for both power and signal terminals.

- For IDC / crimp types, use matched tooling and press-force to ensure full insulation displacement; for solder types, follow a controlled soldering profile to avoid overheating the LCP housing.

- Insert and pull out the connector along the mating direction, avoid pulling on the cable itself, and do not exceed the specified mating/unmating force or durability cycles.

- Keep gold-plated contact areas clean and dry, avoid touching them with bare fingers, and store products in dry anti-static packaging before assembly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!