Our SAS 3.0/4.0 series connectors deliver exceptional data transfer speeds of up to 24 Gb/s, ensuring stable and efficient transmission for enterprise storage and server systems. Designed with high reliability and hot-plug capability, each connector undergoes strict quality control and automated precision manufacturing. With flexible customization options and strong R&D support, our SAS connectors are ideal for both board-to-board and wire-to-board applications in enterprise storage systems, servers, and data centers requiring consistent, high-speed performance. ShuangYi Precision — Powering Smarter Connections.

ShuangYi Precision — Powering Smarter Connections.

Why Choose Us:

• Free samples available for quality evaluation.

• Support for both OEM & ODM customization.

• Trade Terms: EXW, FOB, CIF, CPT, etc.

Notice: The displayed price is only for reference. Contact us now for the best offer and detailed quotation!

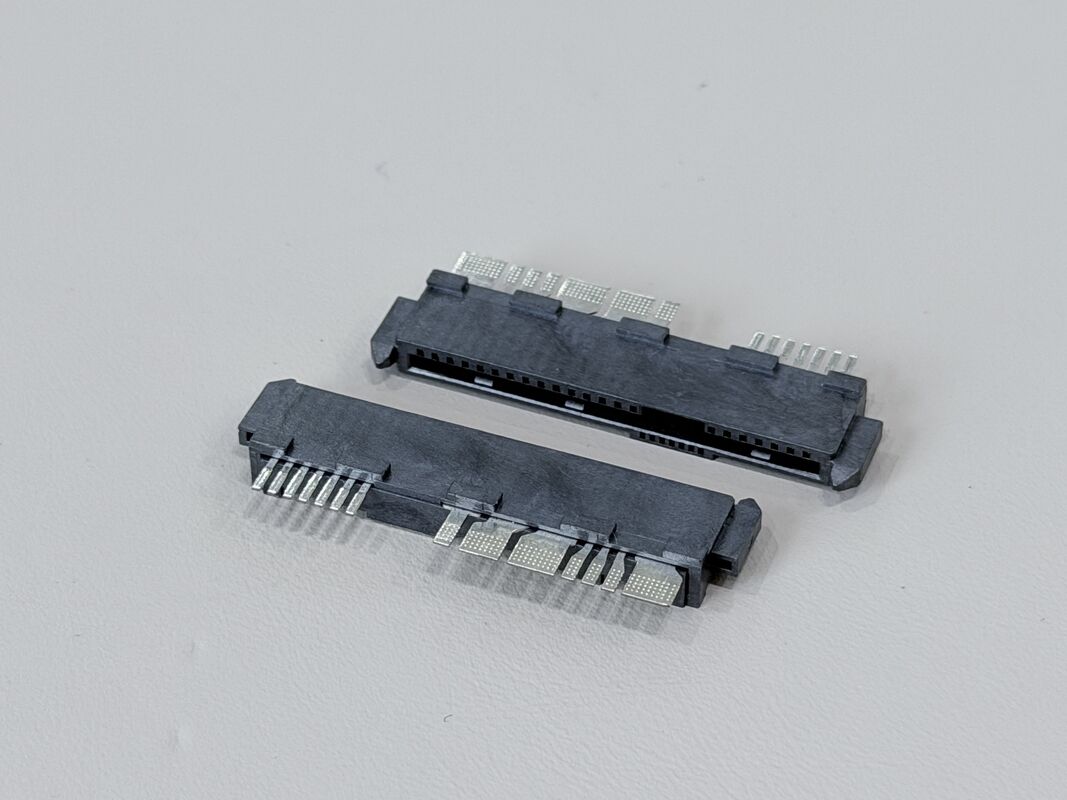

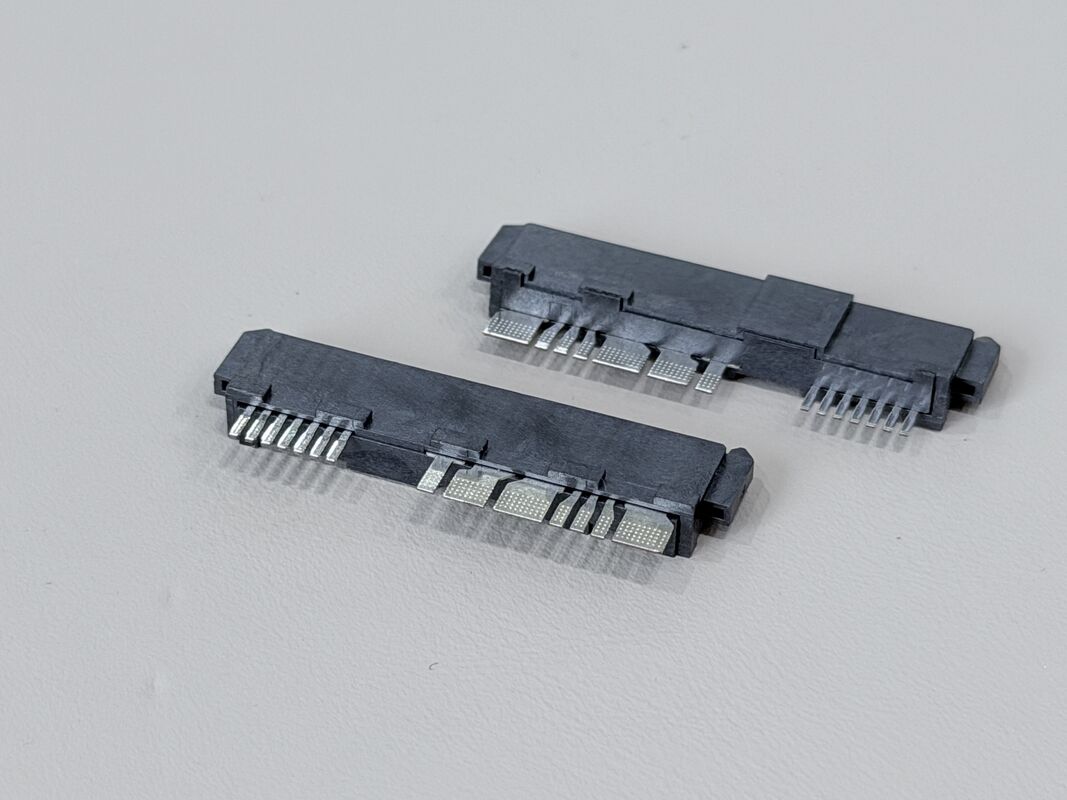

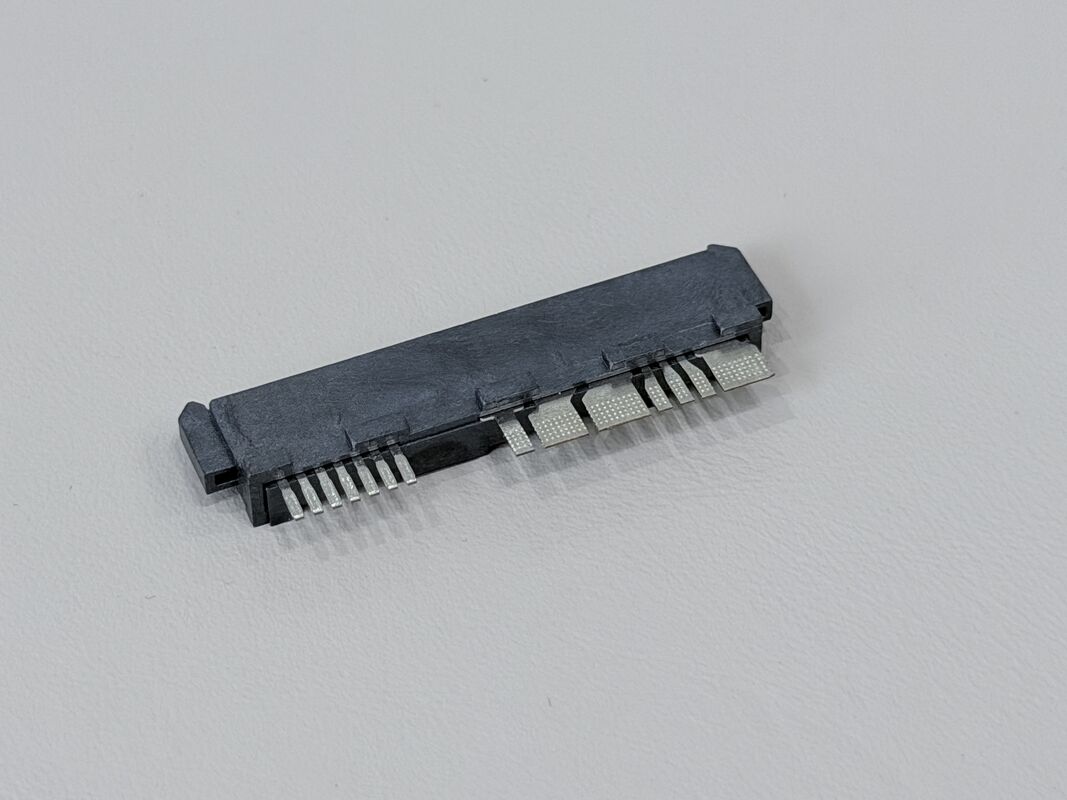

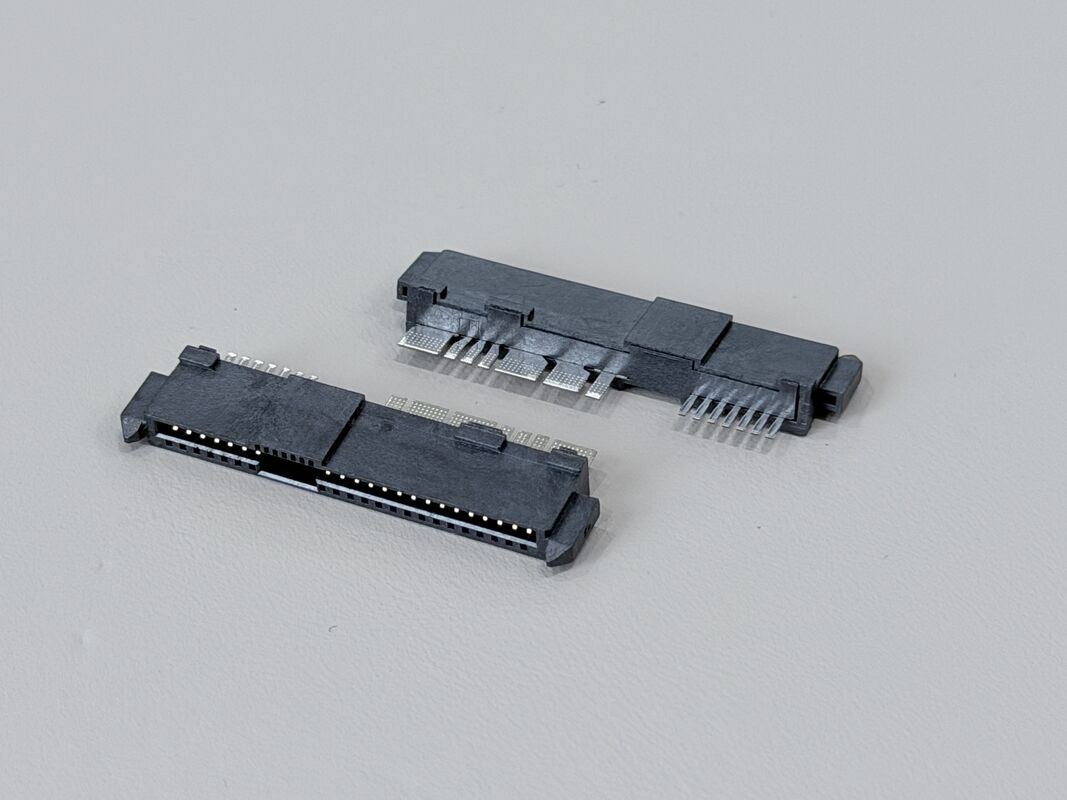

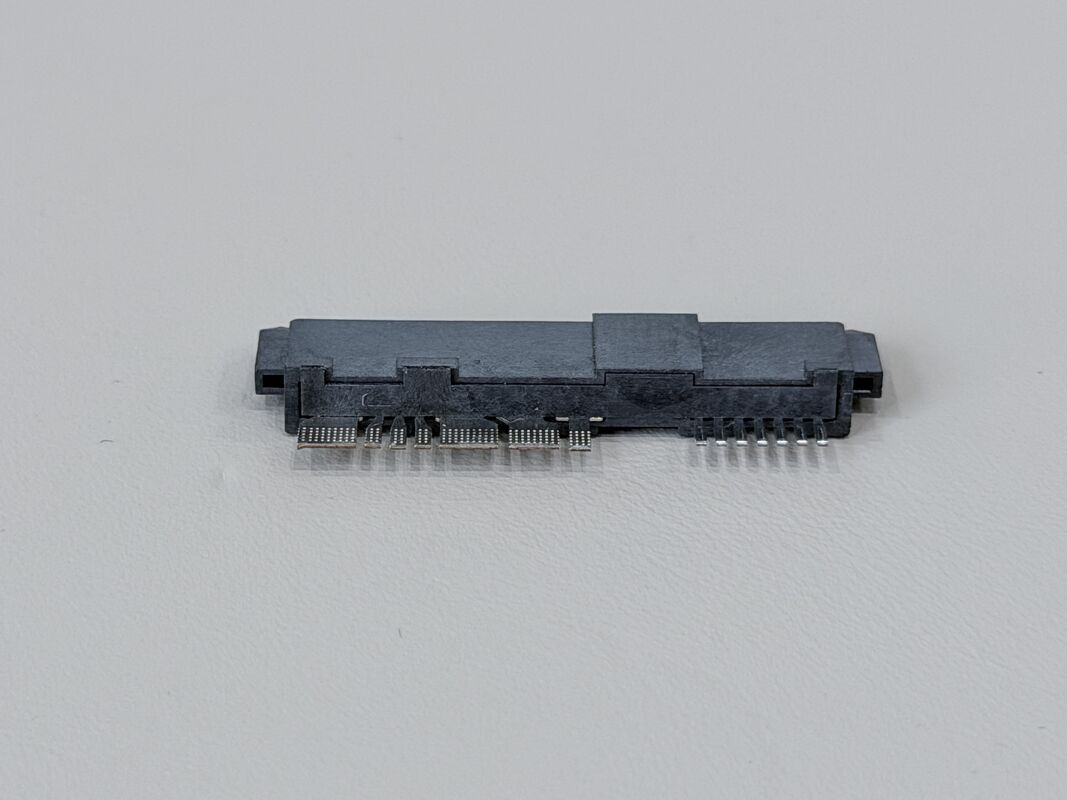

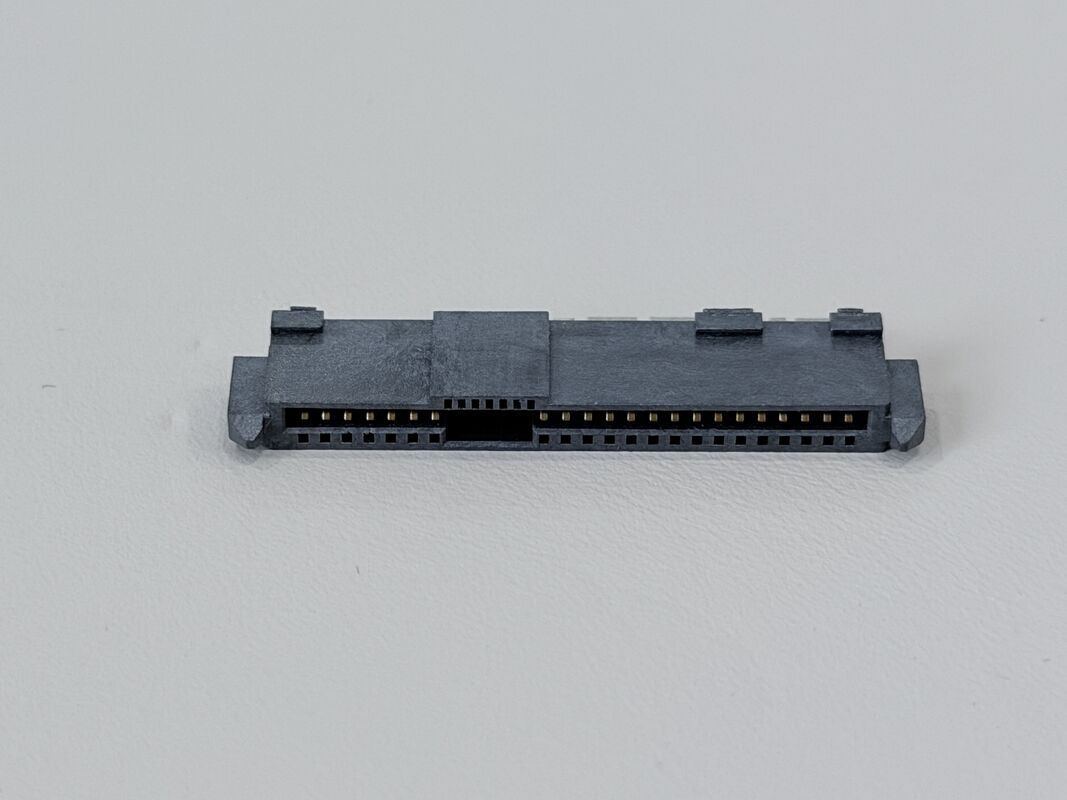

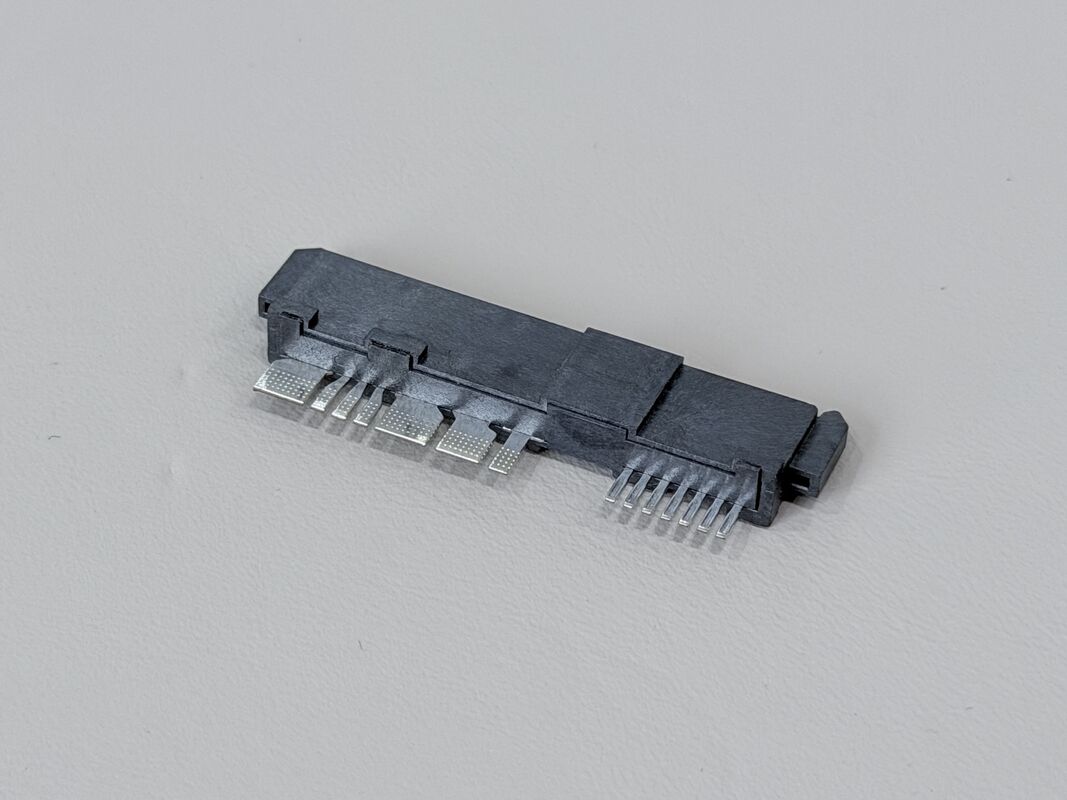

The SAS 29P Solder-Type Female Cable Connector 180° with Positioning Peg & Top Boss is a robust electronic signal and power connector designed for SAS-based server, storage and industrial applications. With a 1.27mm pitch housing and 29 female pins, it enables compact, high-density wire and cable assemblies between backplanes, test fixtures or dummy ports and controller boards.

Each terminal is made from phosphor bronze C5191-H (t = 0.25mm) and receives a three-layer plating system:

-

50u" minimum nickel over the entire terminal for corrosion resistance,

-

15u" minimum gold on the contact area to ensure low contact resistance and stable high-speed electrical signal performance,

-

80u" minimum tin on the solder tail for strong solder joints to copper wires in cable harnesses.

The glass-filled LCP housing (black, UL94-V0, Halogen-Free) offers excellent mechanical strength, dimensional stability and heat resistance, making the connector suitable for demanding electrical and electronic equipment.

Electrically, the connector is rated at 1.5A @ 40VAC, with contact resistance ≤30mΩ, insulation resistance ≥1000MΩ, and withstand voltage 500VAC/minute. Mechanical specifications define mating and unmating forces for both backplane and cable, and single pin retention ≥0.8kgf, ensuring that terminals remain secure even under vibration and handling.

The positioning peg and top boss help align the connector accurately in jigs, housings or over-molded shells, simplifying assembly and improving reliability for customized wire, cable and PCB interconnect solutions.

| Product Type |

SAS “dummy” 29P female cable connector, 180° straight, wire solder type, with positioning peg and top boss |

| Interface Series |

SAS series |

| Number of Positions |

29 pins (29P) |

| Pitch of Housing |

1.27mm (C: 1.27 pitch of housing) |

| Gender |

Female connector |

| Links Way of Terminal with Wire |

S43: solder way of 180° terminal with wire (soldered cable type) |

| Plating Specification Code |

A5: Au 15u" plated |

| Rated Current / Voltage |

1.5A @ 40VAC |

| Operating Temperature |

–20°C to +85°C |

| Contact Resistance |

≤ 30mΩ (Max) |

| Withstand Voltage |

500VAC / minute |

| Insulation Resistance |

≥ 1000MΩ (Min) |

| Terminal Plating – Base |

Ni 50u" min plated over terminal |

| Contact Area Plating |

Au 15u" min plated on contact area |

| Solder & Crimp Area Plating |

Sn 80u" min plated on solder & crimp area |

| Mating Force |

Backplane ≤ 25N max; Cable ≤ 50N max |

| Unmating Force |

Backplane ≥ 5N min; Cable ≥ 20N min |

| Single Pin Retention Force |

≥ 0.8kgf per pin |

| Durability Test – Frequency |

200 cycles/hour, 25 cycles |

| Durability After Test |

Contact resistance per pin ≤ 30mΩ, no distortion, split, curliness or cracks |

| Salt Spray Test |

Gold-plated area ≥ 48 hours (salt spray) |

| Housing Material |

LCP G/F, Black, UL94-V0, Halogen-Free (HF) |

| Terminal Material |

Phosphor Bronze C5191-H, t = 0.25mm (TS-C07F-S04, TS-C15F-S86) |

| Environmental Compliance |

RoHS 2.0 + HF |

| Special Features |

Positioning peg for accurate location; straight body with top boss for mechanical guidance and locking; wire solder tail for cable assembly |

Key Features

- SAS 29P, 1.27mm pitch solder-type female connector designed for high-density wire and cable applications

- Ni 50u" + Au 15u" contact plating provides low contact resistance, excellent conductivity and corrosion resistance

- Sn 80u" min on solder area ensures reliable electrical and mechanical bonding with copper wires

- Phosphor bronze C5191-H terminals offer stable spring force and durability under vibration and repeated insertion/removal

- LCP G/F black UL94-V0, HF housing delivers high mechanical strength and heat resistance for harsh server, automotive and industrial environments

- Defined mating/unmating forces for both backplane and cable help protect terminals and maintain consistent connection quality

- Single pin retention ≥0.8kgf prevents terminal back-out during assembly, cable pulling or long-term use

- Positioning peg and top boss provide precise mechanical guidance and locking, ideal for over-molding and custom connector shells

- Fully RoHS 2.0 + Halogen-Free compliant, suitable for global electrical and electronic markets

⚙️ Applications

- This SAS 29P IDC female connector is suitable for a wide range of wire / cable / electrical uses:

- Server & Data Center Wiring Harness

- SAS dummy or alignment connectors in backplane harnesses

- Internal server cable assemblies between controller boards and mechanical interfaces

- Storage & Communication Equipment

- Cable harnesses in disk arrays, JBOD, NAS and test fixtures

- Communication equipment where SAS-style connectors are used for signal or power routing

- Automotive & Industrial Electronics

- Industrial PCs, data logging systems and test jigs requiring robust SAS-style cable connectors

- Vehicle and equipment harnesses where high-density, reliable electrical connector performance is required

- Custom Wire & Cable Assemblies

- OEM / ODM wire cable electronic connector solutions for PCB-to-cable or cable-to-cable transmission

- Mechanical dummy or keying connectors in fixtures, test boards and simulation systems

⚠️ Notes

- Select appropriate wire gauge and insulation according to the 1.5A @ 40VAC rating and application requirements (signal + power).

- Use the recommended soldering process for the tin-plated tails; ensure sufficient solder wetting for low resistance and high pull-out strength.

- Keep the gold-plated contact area clean; avoid touching terminals with bare fingers to prevent contamination and oxidation.

- When assembling, make full use of the positioning peg and top boss to align the connector correctly in fixtures or housings, reducing stress on the terminals and PCB.

- Do not exceed the specified mating/unmating forces for backplane and cable to maintain terminal elasticity and connector lifetime.

- After durability testing (up to 25 cycles at 200 cycles/hour), verify that contact resistance per pin remains ≤30mΩ and that no distortion, cracks or deformation appear.

- Store connectors in dry, anti-static packaging, and handle them in ESD-protected areas when integrating into sensitive electronic systems.

- Operate only within the specified temperature range (–20°C to +85°C) and electrical ratings to guarantee long-term reliability.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!