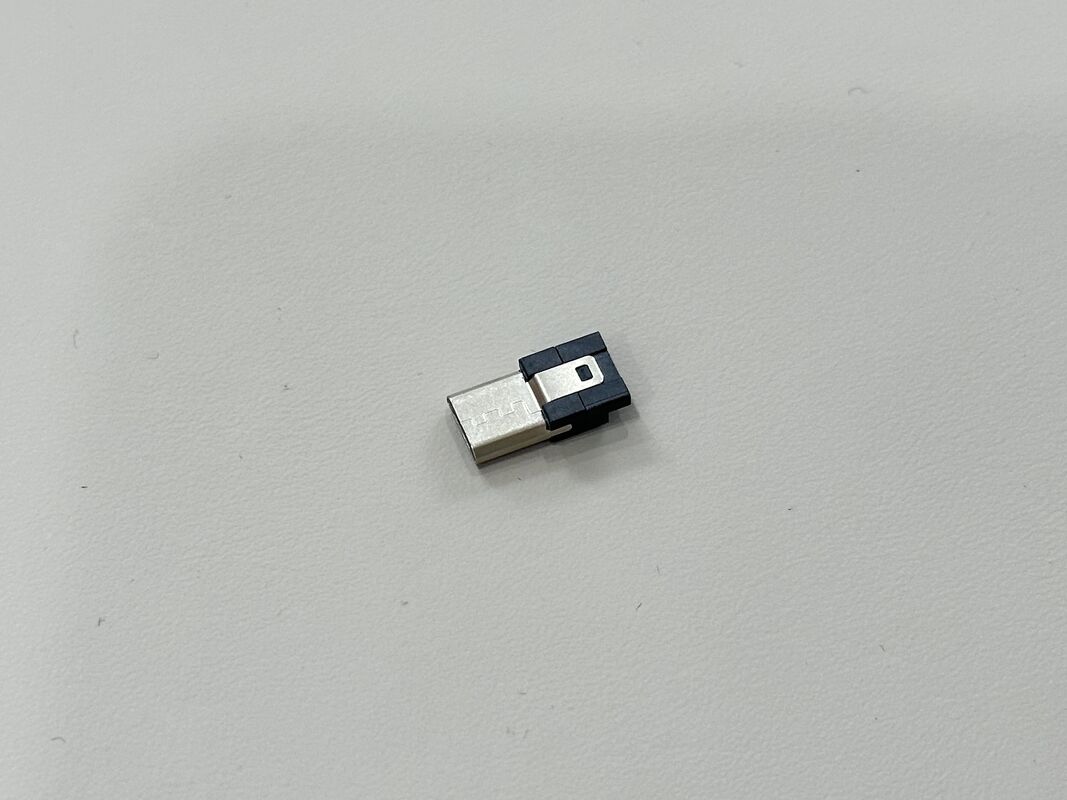

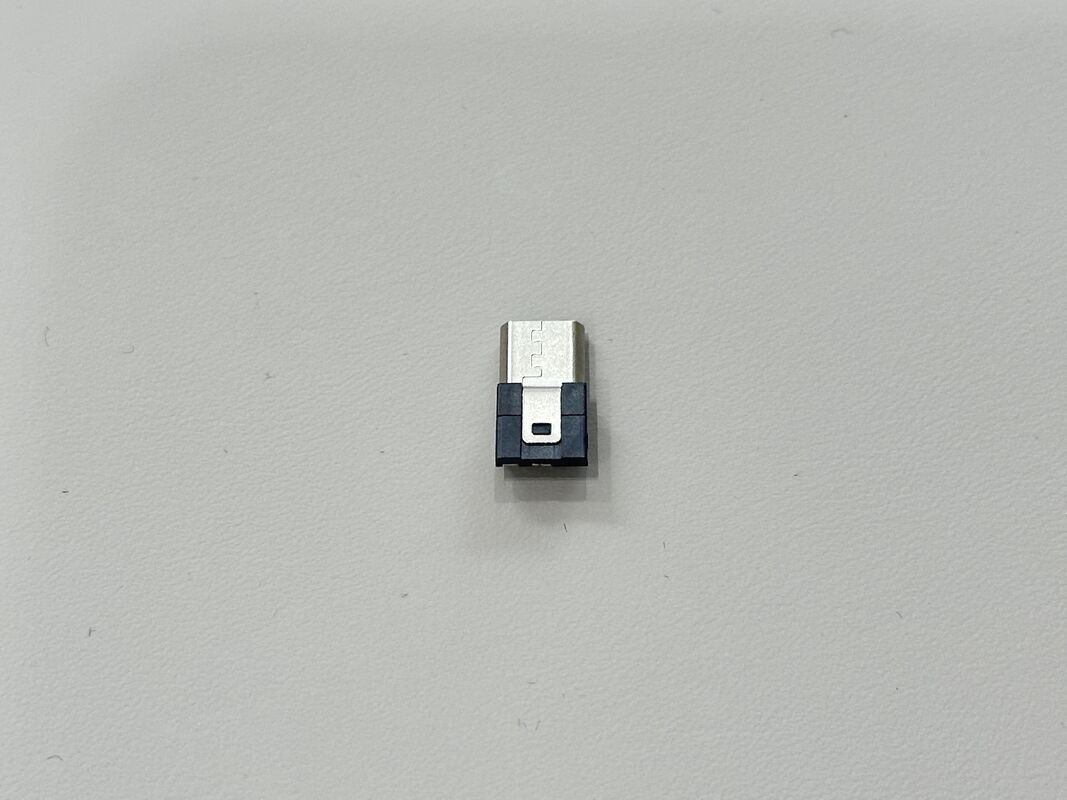

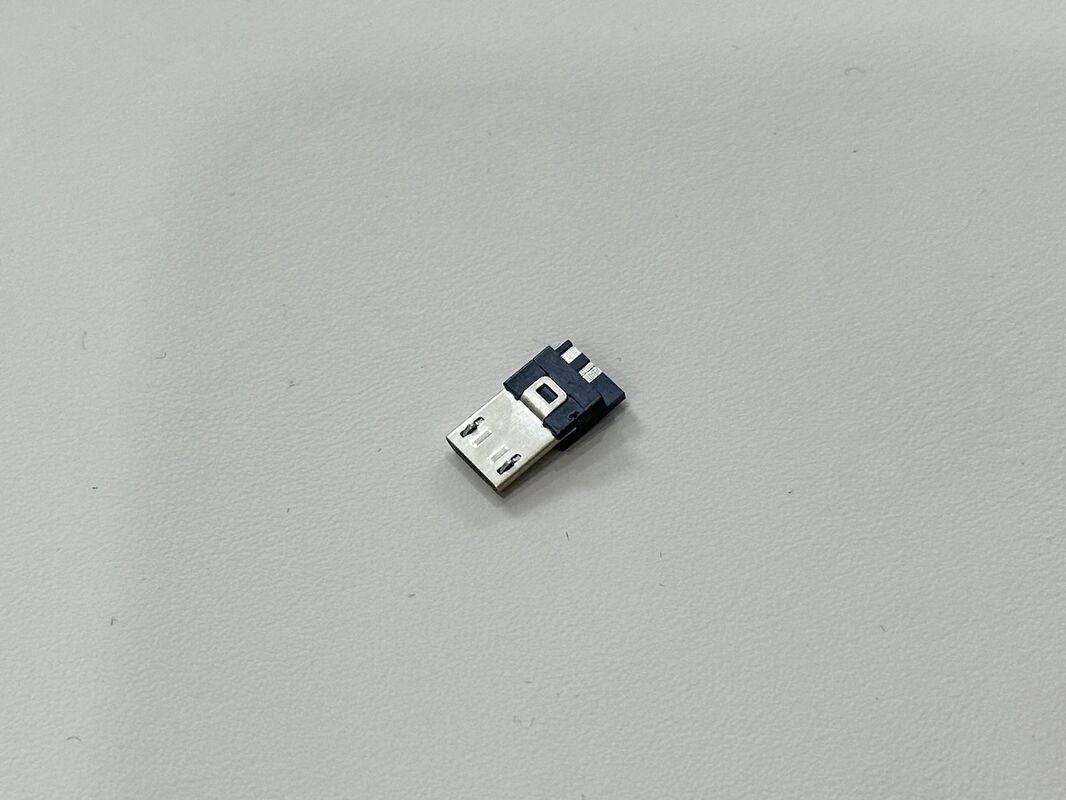

Product Description

This Micro USB 5-pin male connector is designed as a compact cable-end solution for power and high-speed signal transmission in consumer and industrial electronics. The metal shell and precision plastic housing provide stable alignment and reliable plug-in with standard Micro-B receptacles, while the gold-plated terminals maintain low contact resistance over thousands of mating cycles. Nickel and tin plating on the solder and crimp areas improve solderability and long-term corrosion resistance, making it suitable for harsh electrical environments.

The connector is optimized for assembly onto multi-core wire or custom wire harnesses, supporting 5 V power and USB 2.0 data lines. With a −20 °C to +85 °C working temperature range and robust mechanical characteristics, it can be used in portable electronic devices, smart sensors, automotive accessories, communication terminals, and embedded control boards where compact size and stable data transmission are required.

| Connector type |

Micro USB (USB Micro-B) 5-pin male connector |

| Mounting style |

Wire-end cable connector, solder/crimp terminals |

| Number of pins |

5 pins (power + data signal + ID + ground) |

| Pitch |

0.65 mm (contact spacing, compact layout) |

| Rated current |

1.0 A per signal pin (PIN 2,3,4), up to 1.8 A on power pins (PIN 1,5) |

| Rated voltage |

5 V DC typical USB power |

| Contact resistance |

≤ 30 mΩ (initial) |

| Insulation resistance |

≥ 1000 MΩ at 500 VDC |

| Dielectric withstand |

500 VAC / minute between contacts and shell |

| Operating temperature |

−20 °C to +85 °C |

| Plating – terminals |

≥ 50 µ" Ni under-plating, Au over contact area, Sn over solder / crimp area |

| Plating – shell |

≥ 50 µ" Ni on metal shell |

| Housing material |

High-temperature thermoplastic, UL94-V0 |

| Shell material |

Copper alloy shield, nickel plated |

| Insertion force |

≤ 35 N |

| Extraction force |

≥ 10 N after 10,000 mating cycles |

| Durability |

10,000+ mating cycles |

| Wire termination |

Solder / crimp to discrete wires or wire harness |

| Compliance |

RoHS, halogen-free options available |

| Customization |

Wire gauge, cable length, housing color, plating thickness, logo printing |

Application Fields

Power and data cable assemblies for mobile devices, handheld terminals, barcode scanners, POS machines and IoT gateways

Custom wire harnesses for automotive infotainment, GPS trackers, DVRs and dashboard electronics

PCB-to-wire interconnection for small industrial controllers, medical instruments, smart meters and communication modules

Server, router and storage peripherals where Micro USB is used for configuration, firmware upgrades or auxiliary power

Precautions

Ensure correct pin assignment for VBUS, D+, D−, ID and GND when designing the cable or harness to avoid damage to the host or device.

Observe the rated current on power pins; overspec load or poor heat dissipation may lead to connector overheating.

Use appropriate wire gauge and strain-relief design so that bending or pulling forces are not directly applied to the solder or crimp terminals.

Keep the contact area clean and free of flux residue, dust or moisture to maintain low contact resistance and stable signal quality.

When used in automotive, outdoor or high-vibration applications, combine the connector with proper overmolding, housing support or additional mechanical locking to enhance reliability.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!