Our SATA connector series is designed for stable data transmission and high reliability. With customizable pin count, pitch, materials, and plating specifications, we offer tailored solutions for diverse applications. Produced in our automated facilities with strict quality control, these connectors ensure excellent durability, heat resistance, and hot-swap performance. Widely used in computers, servers, and industrial storage devices, they deliver precision connection and long-lasting performance.

ShuangYi Precision — Powering Smarter Connections.

Why Choose Us:

• Free samples available for quality evaluation.

• Support for both OEM & ODM customization.

• Trade Terms: EXW, FOB, CIF, CPT, etc.

Notice: The displayed price is only for reference. Contact us now for the best offer and detailed quotation!

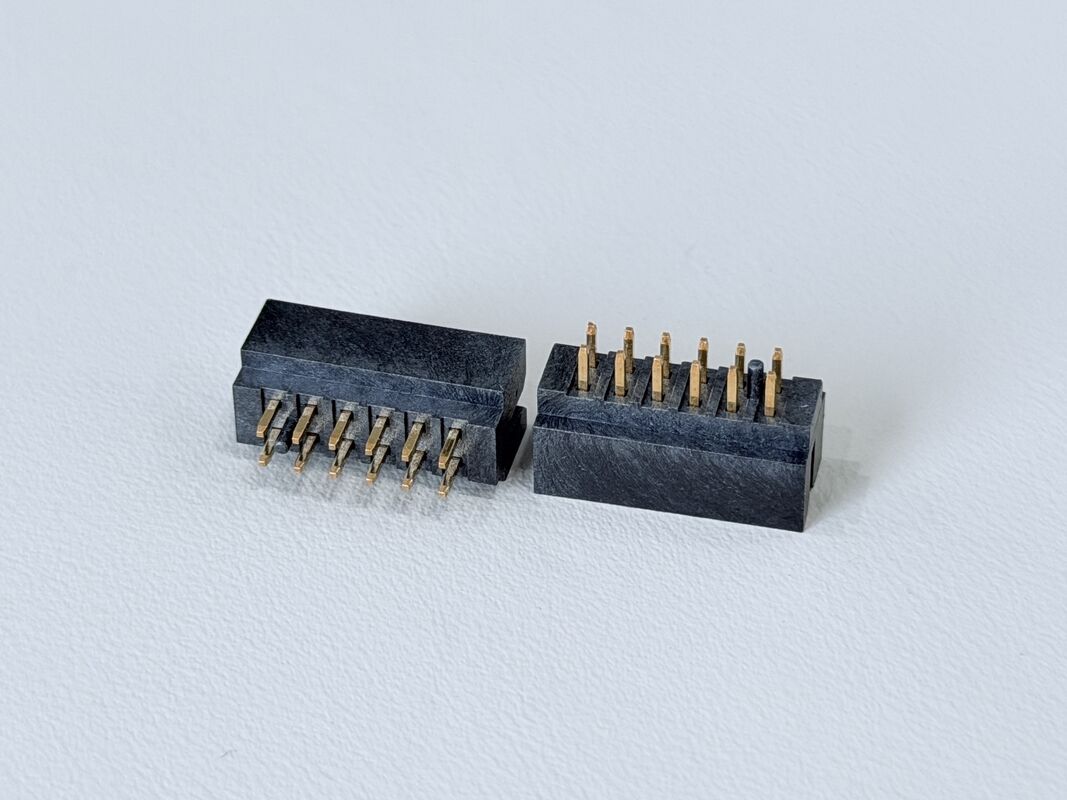

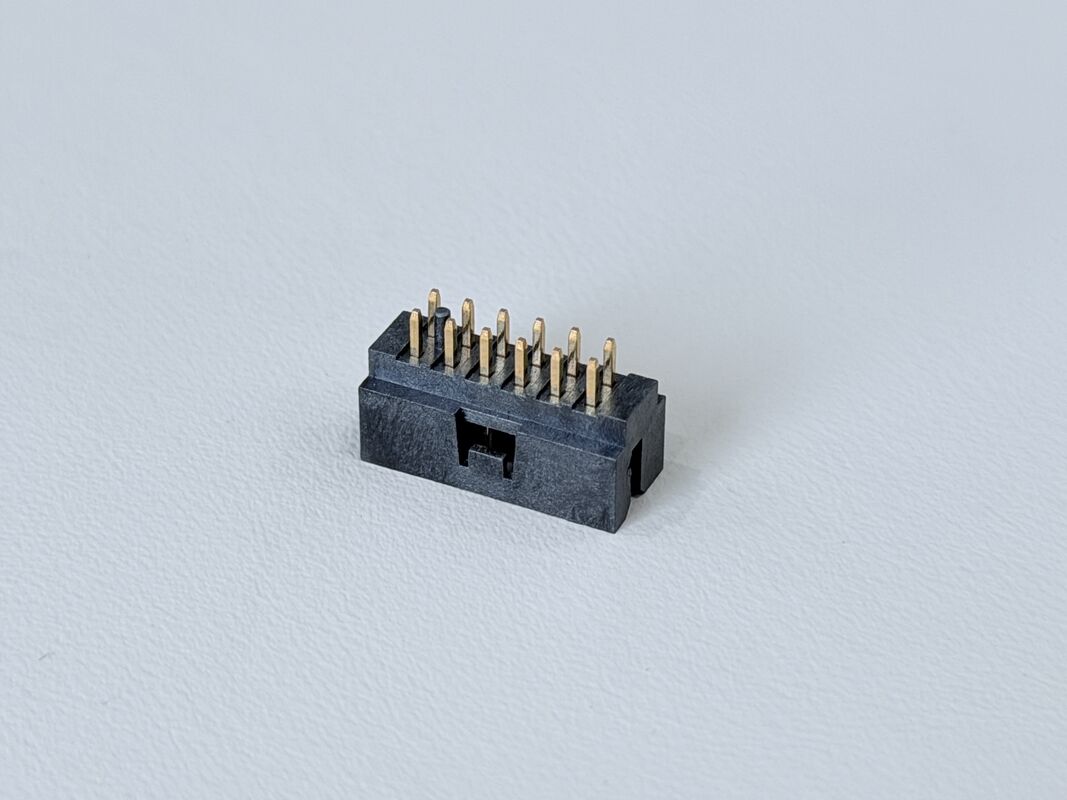

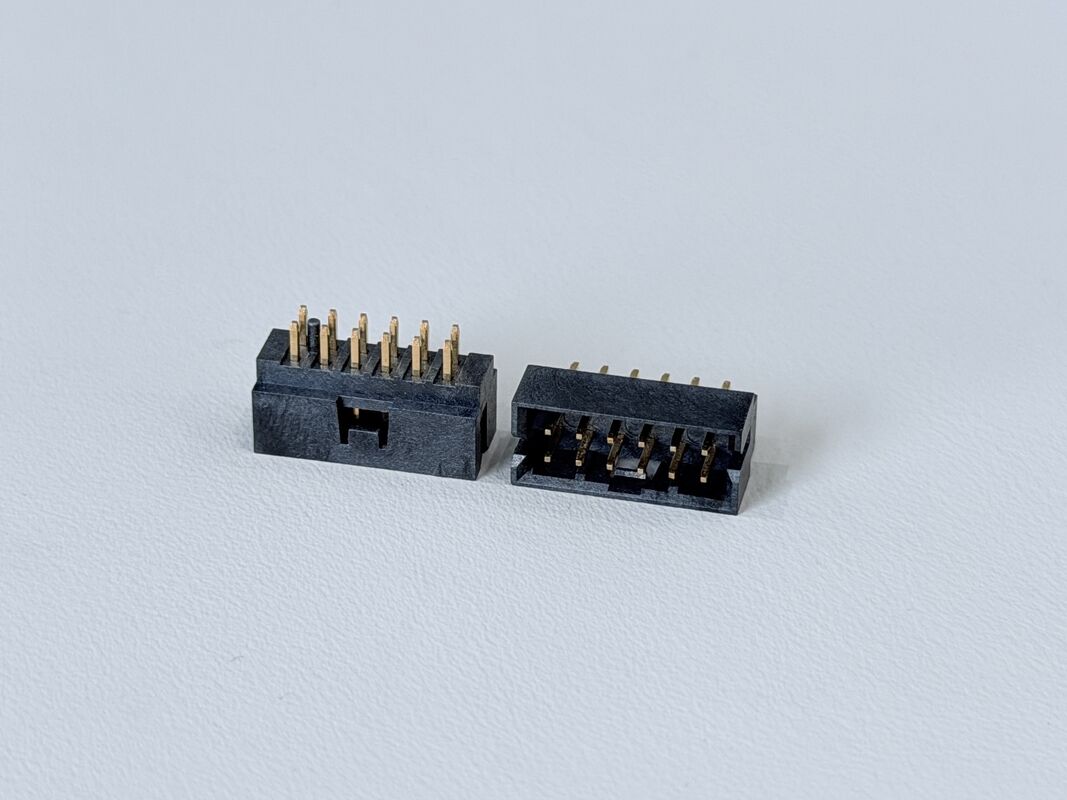

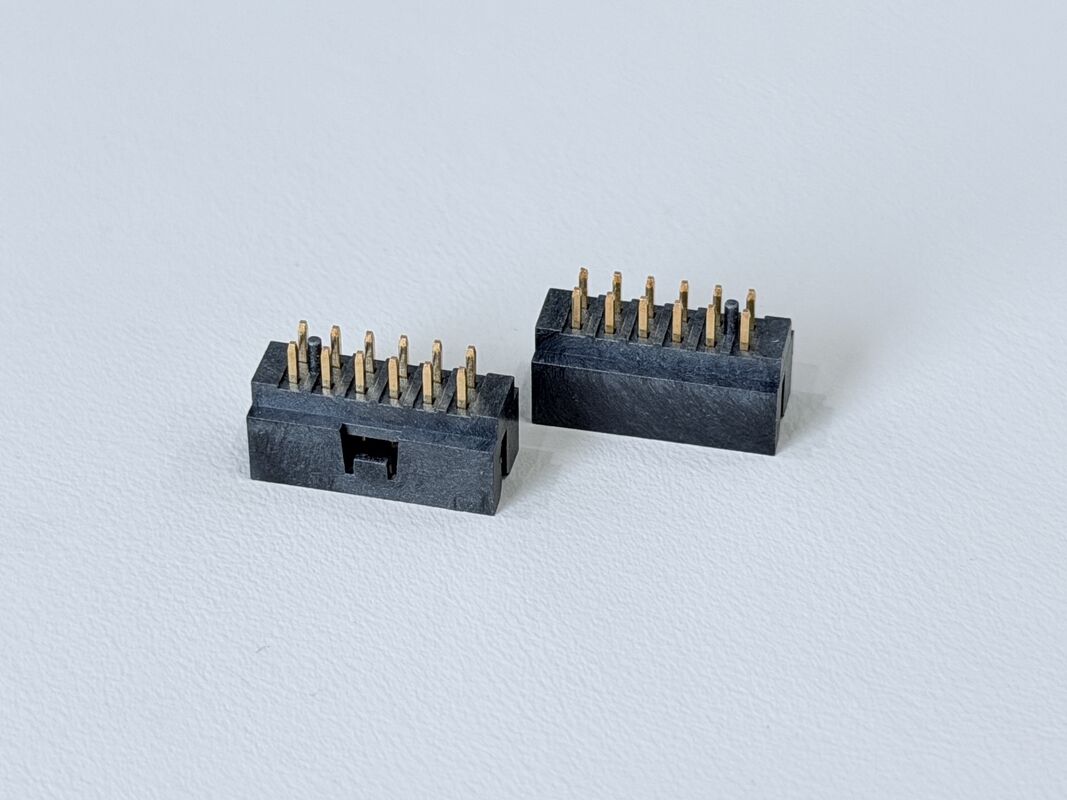

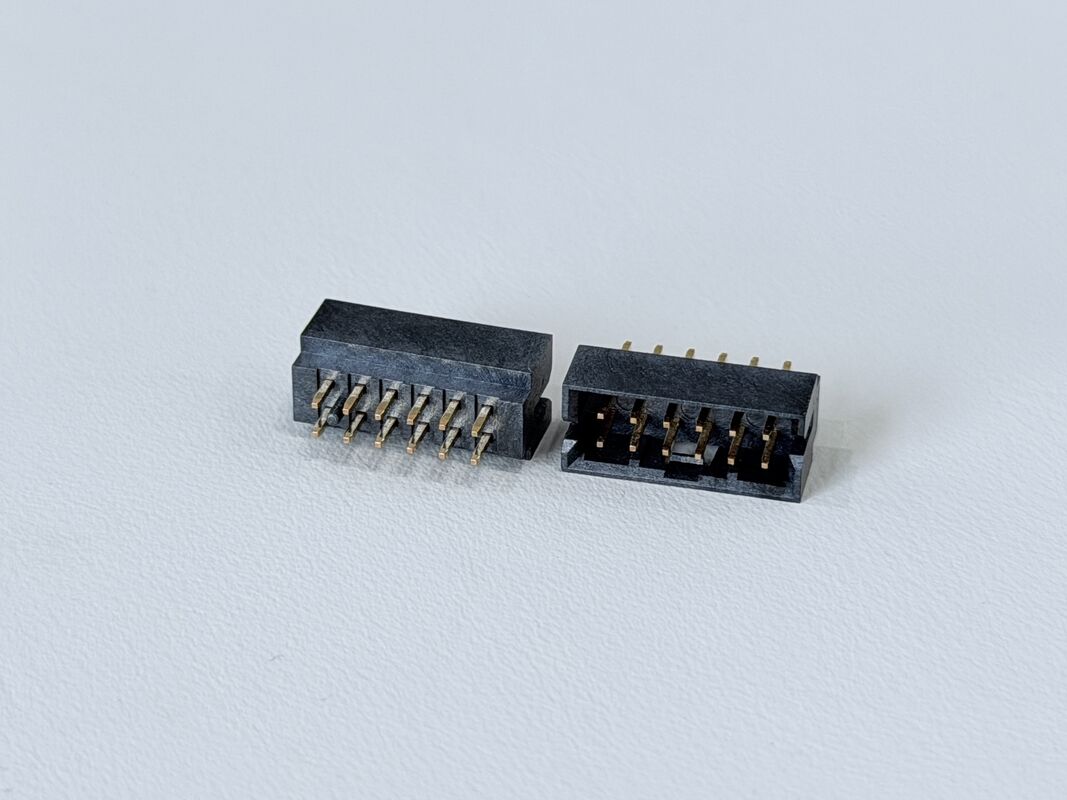

This 2.00mm pitch dual-row pin header connector is designed for reliable PCB-to-PCB and wire-to-board electrical signal transmission. Built with a UL94-V0 flame-retardant LCP housing and high-conductivity H65 copper terminals, it provides excellent mechanical strength and long-term stability. The terminals are finished with 50µ" nickel plating and 15µ" gold flash, ensuring low contact resistance, enhanced corrosion resistance, and stable signal integrity in demanding environments.

With a rated current of 2A per pin and an operating temperature from -25°C to +85°C, this connector is suitable for compact PCB layouts and mid-power applications. It is widely used in automotive electronics, industrial automation equipment, servers, power modules, home appliances, and consumer electronics.

This model supports consistent solderability, strong retention force, and high reliability during repeated mating cycles, making it an ideal choice for OEM/ODM customization and high-volume PCB assembly.

| Product Type |

2.00mm Pitch Dual-Row Pin Header Connector |

| Pin Configuration |

2×6 Pins (12 Pins total) |

| Mounting Type |

Vertical PCB Mount with Post |

| Material – Housing |

LCP E130i Black, UL94-V0 |

| Material – Terminal |

Copper Alloy H65 |

| Plating |

50µ" Nickel Under-Plating, 15µ" Gold Flash on Contact Area, salt-spray 24h |

| Pitch |

2.00mm |

| Rated Current |

Up to 2A per pin |

| Operating Temperature |

-25°C to +85°C |

| Contact Resistance |

≤10mΩ Initial, ≤20mΩ After Test |

| Insulation Resistance |

≥1000MΩ MIN |

| Dielectric Withstanding Voltage |

250V DC / 800V AC per minute |

| Pin Retention Force |

≥1.0Kgf (before reflow) |

| Environmental |

HF / RoHS 2.0 compliant |

| Application Type |

Electrical & electronic PCB interconnection |

⚙️ Applications

- PCB Signal & Data Transmission: Used for board-to-board or board-to-module connections, including low-voltage signals, data transmission, and control interfaces.

- Consumer Electronics: Common in smart home appliances, printers, cameras, displays, controllers, and handheld devices for internal signal routing.

- Industrial Automation & Control Systems: Applied in PLCs, industrial control boards, sensors, meters, robotics modules, and automation I/O interfaces.

- Servers & Data Center Equipment: Used for backplane interfaces, storage modules, communication boards, and signal expansion connectors.

- Automotive Electronics: Suitable for ECUs, BMS modules, sensor units, dashboards, infotainment systems, and on-board control interfaces.

- Communication & Networking Devices: Used in routers, switches, IoT gateways, RF modules, and network communication cards.

- IoT & Smart Device Modules: Applied in Bluetooth modules, WiFi modules, GPS/Beidou modules, sensor nodes, and embedded system expansion ports.

- Power Control & Monitoring Boards: For auxiliary power transmission, monitoring signals, and low-power control circuits.

- Custom OEM/ODM Electronic Designs: Ideal for designs requiring customizable pin count, pitch, height, plating option, and configuration.

⚠️ Notes

- Ensure Correct Pin Alignment: Check orientation and positioning before mating to avoid mis-insertion, bent pins, or PCB pad damage.

- Do Not Exceed Electrical Ratings: Follow the specified current and voltage limits to prevent overheating or contact failure.

- Proper Insertion and Extraction Force: Avoid excessive force during mating/unmating to prevent deformation, cracked solder joints, or pin damage.

- Keep Contact Surfaces Clean: Ensure terminals remain free from dust, oil, oxidation, or contaminants that reduce conductivity.

- Follow Recommended Soldering Conditions: Use appropriate soldering temperature profiles according to plastic materials such as LCP, PA6T, PA66, or PBT.

- Verify PCB Hole Tolerance: Incorrect hole size may cause inadequate solder filling or mechanical instability.

- Avoid Mechanical Stress After Assembly: Do not apply lateral pressure or bending forces, especially for SMT pin headers.

- Maintain Proper Storage Conditions: Store in a dry, dust-free environment to prevent terminal oxidation; use anti-static packaging if required.

- Confirm Compatibility with Female Header: Ensure matching pitch, pin count, height, and contact design to avoid mating failure.

- Choose Correct Plating Specification: Select proper plating (gold, tin, nickel) based on your application’s durability, corrosion resistance, and signal reliability needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!