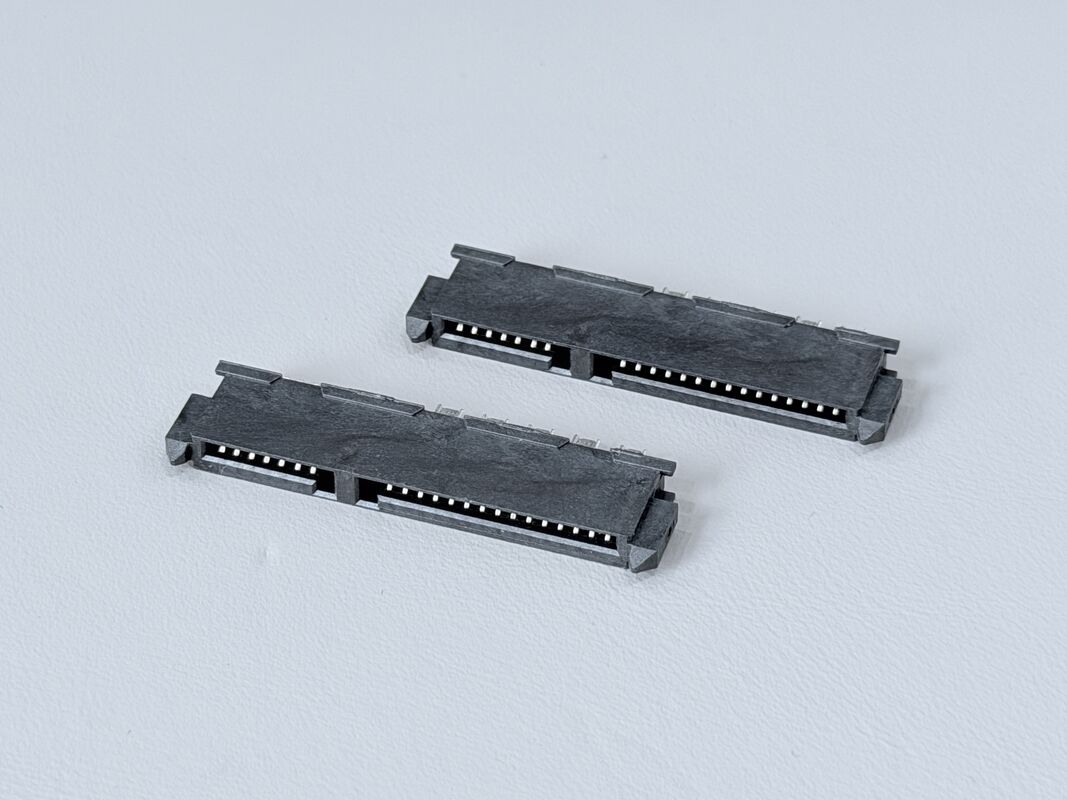

Our SATA connector series is designed for stable data transmission and high reliability. With customizable pin count, pitch, materials, and plating specifications, we offer tailored solutions for diverse applications. Produced in our automated facilities with strict quality control, these connectors ensure excellent durability, heat resistance, and hot-swap performance. Widely used in computers, servers, and industrial storage devices, they deliver precision connection and long-lasting performance.

ShuangYi Precision — Powering Smarter Connections.

Why Choose Us:

• Free samples available for quality evaluation.

• Support for both OEM & ODM customization.

• Trade Terms: EXW, FOB, CIF, CPT, etc.

Notice: The displayed price is only for reference. Contact us now for the best offer and detailed quotation!

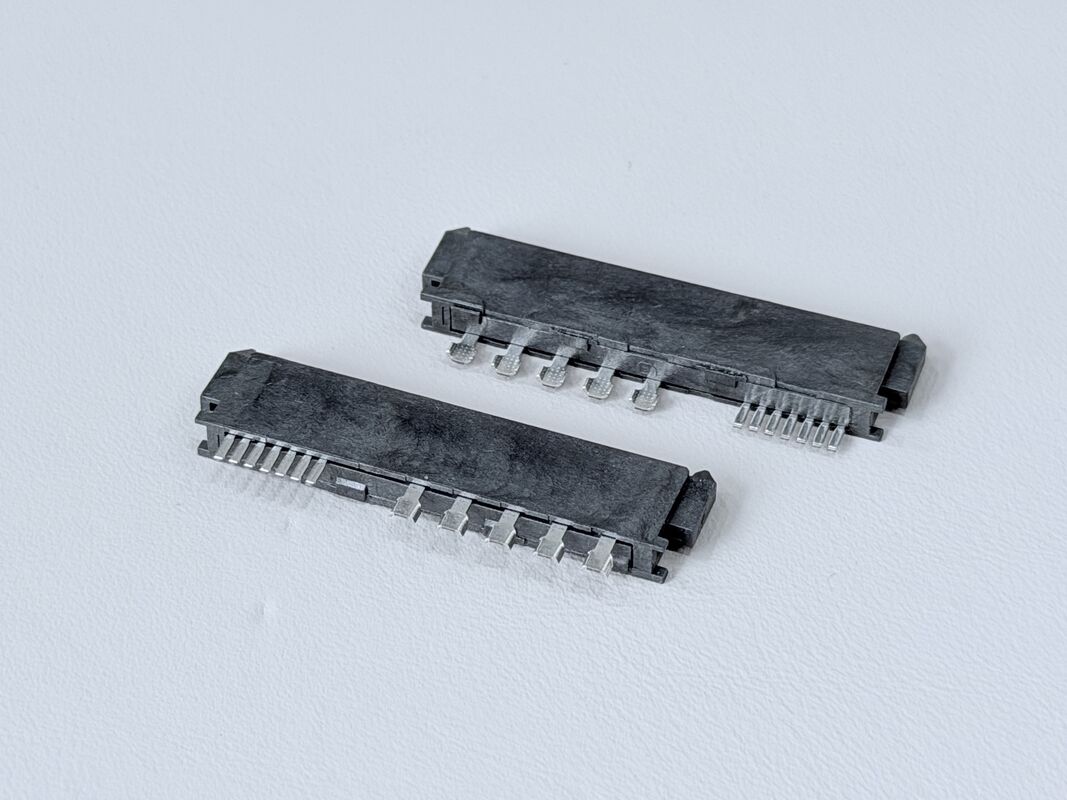

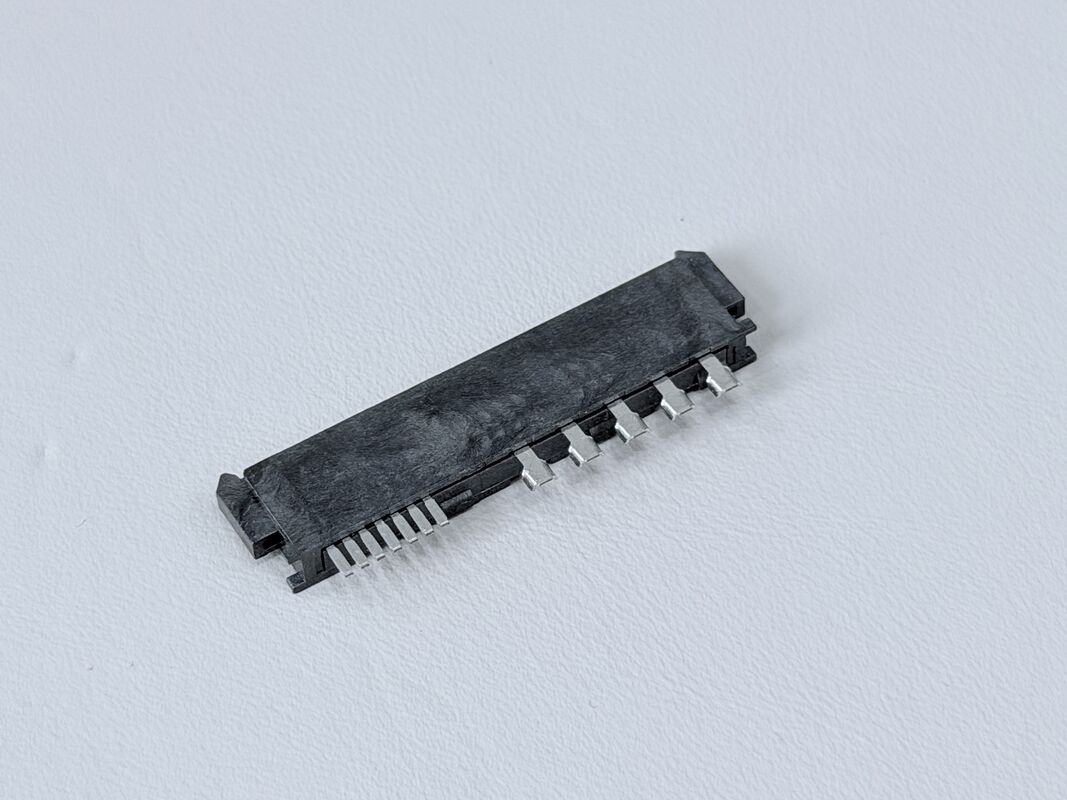

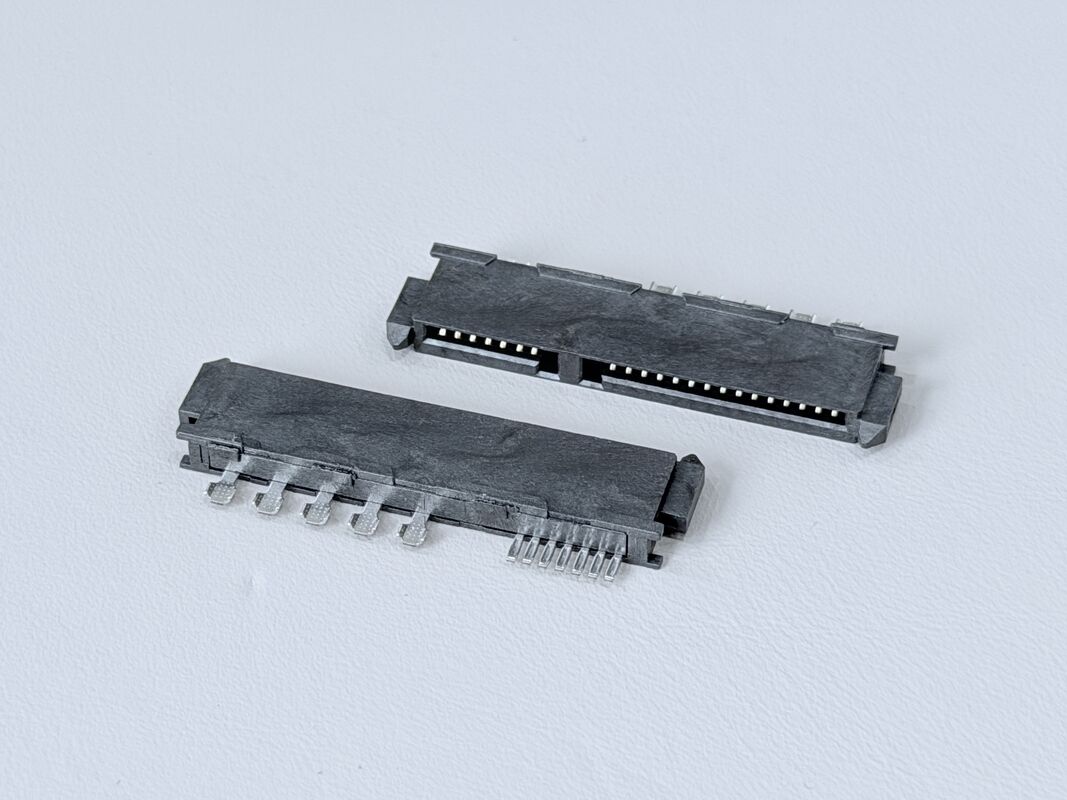

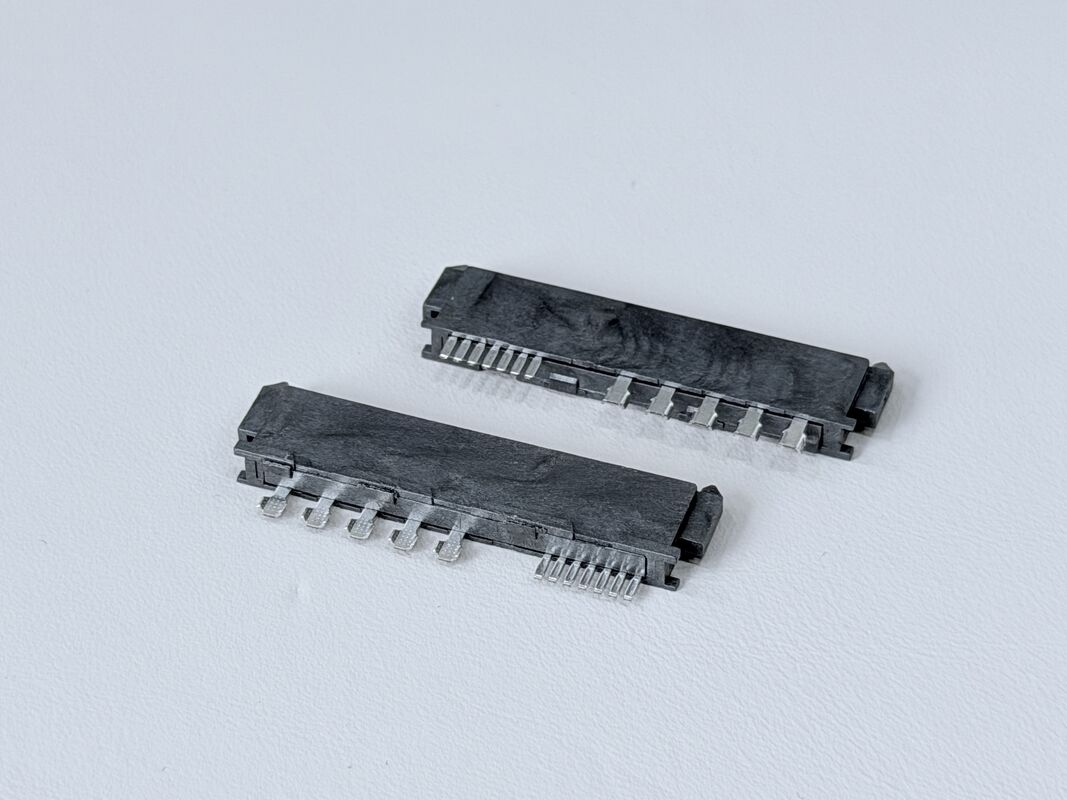

The SATA 22P Female Connector is a 32-wire solder type design with a 180° orientation, offering stable electrical performance for SATA power and signal transmission.

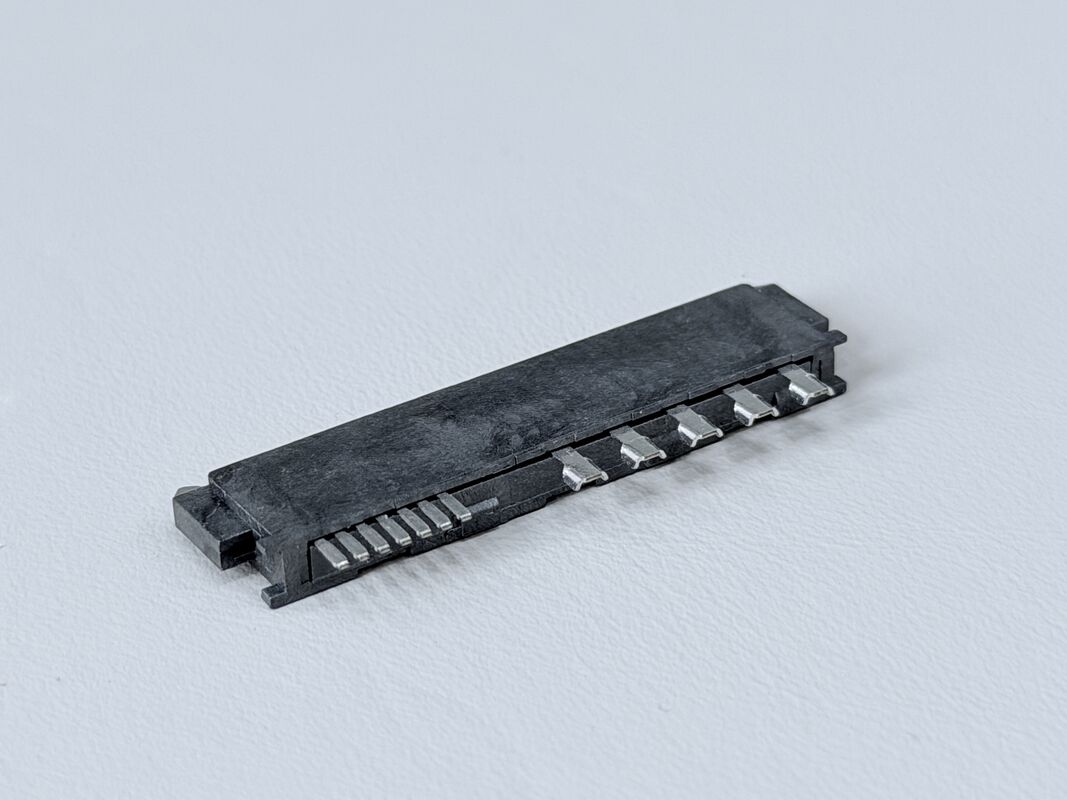

The connector features G/F (gold flash) plating on the contact area, with terminals constructed from C5191 phosphor bronze (T=0.25) for enhanced strength and reliability.

The terminal structure includes ≥50µ” nickel plating, ≥80µ” tin plating on solder areas, and G/F gold plating on the contact points to ensure low resistance and corrosion resistance.

The housing is made from UL94-V0 LCP with glass fiber, providing heat resistance and dimensional stability.

Electrical performance meets the drawing standards:

1.5A @ 40VAC, ≤30mΩ contact resistance, ≥1000MΩ insulation resistance, and 500VAC withstand voltage.

Mechanical performance includes ≤45N mating force, ≥10N unmating force, and ≥0.8kgf pin retention, ensuring long-term reliability.

The connector also passes salt spray ≥24h and a durability test of 200 cycles/h, 50 cycles.

This connector is fully RoHS 2.0 compliant, suitable for high-reliability applications.

| Product Type |

SATA 22P Female Connector, 32-Wire Solder Type, 180° |

| Operation Temperature |

–20°C to +85°C |

| Rated Current |

1.5A @ 40VAC |

| Contact Resistance |

≤ 30mΩ |

| Withstand Voltage |

500VAC/min |

| Insulation Resistance |

≥ 1000MΩ |

| Terminal Plating – Nickel |

Ni ≥ 50µ” |

| Contact Area Gold Plating |

Au G/F (Gold Flash) |

| Tin Plating on Solder/Crimp Area |

Sn ≥ 80µ” |

| Mating Force |

≤ 45N |

| Unmating Force |

≥10N for 50 cycles |

| Single Pin Retention Force |

≥ 0.8kgf |

| Durability Test |

200 cycles/hour, 50 cycles total |

| Salt Spray Test |

≥ 24H |

| Terminal Material |

PH. BRONZE – C5191, T = 0.25 |

| Housing Material |

LCP + G/F, UL94-V0, Black |

| Pitch |

1.27mm |

| Links Way (Code) |

S1: Solder type terminal with wire |

| Plating Code |

A2: Au G/F Plated |

| Environmental Standard |

RoHS 2.0 |

⚙️ Applications

- Server & Data Center Equipment – Used as SAS / SATA electronic signal and power connectors on HDD/SSD backplanes, RAID cards, JBOD/NAS and 1U/2U server boards.

- Communication & Networking Systems – For routers, switches, base stations and other networking equipment that need compact PCB connectors and reliable high-speed transmission.

- Industrial & Automation Electronics – Applied in industrial PCs, PLCs, motion controllers, data loggers and test instruments as PCB-to-wire or cable connectors.

- Automotive & New Energy Applications – Used in in-vehicle data recorders, infotainment units, EV chargers and energy-storage systems for signal and low-power transmission.

- Custom Wire Harness & Cable Assemblies – Suitable for OEM/ODM projects that require connector customization for PCB, wire and cable layouts in electrical and electronic devices.

⚠️ Notes

- Make sure the working voltage, current and temperature of your design stay within the connector’s rated values, with proper safety margin.

- Design PCB pads, holes and mechanical space according to the drawing and pitch, and avoid bending or twisting stress on the connector after soldering or assembly.

- Select appropriate wire gauge, insulation and cable structure based on current load, signal speed and bending requirements for both power and signal terminals.

- For IDC / crimp types, use matched tooling and press-force to ensure full insulation displacement; for solder types, follow a controlled soldering profile to avoid overheating the LCP housing.

- Insert and pull out the connector along the mating direction, avoid pulling on the cable itself, and do not exceed the specified mating/unmating force or durability cycles.

- Keep gold-plated contact areas clean and dry, avoid touching them with bare fingers, and store products in dry anti-static packaging before assembly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!