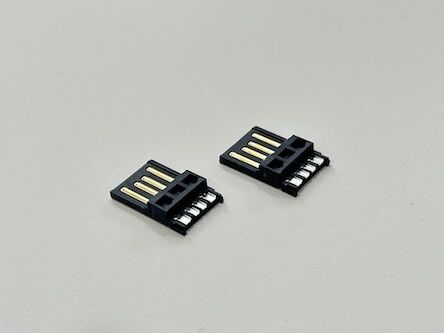

Product Description

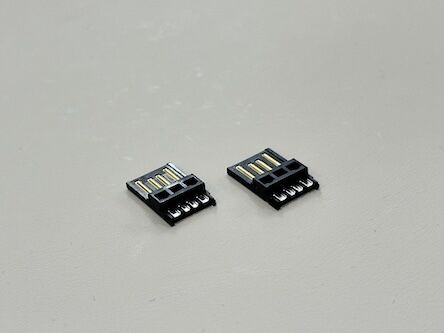

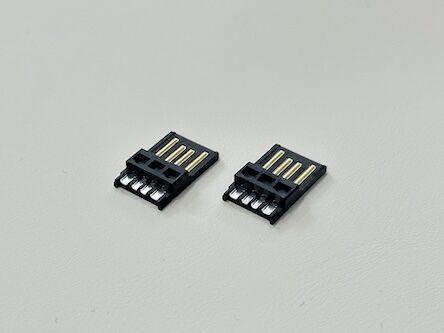

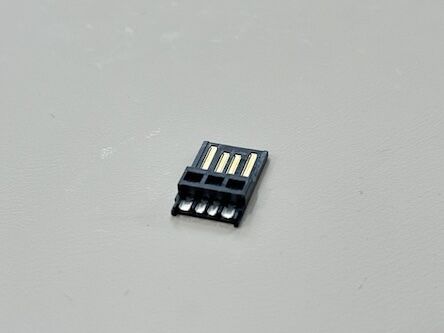

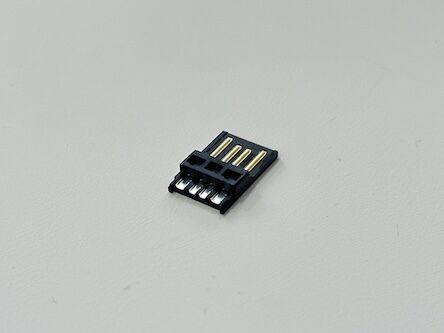

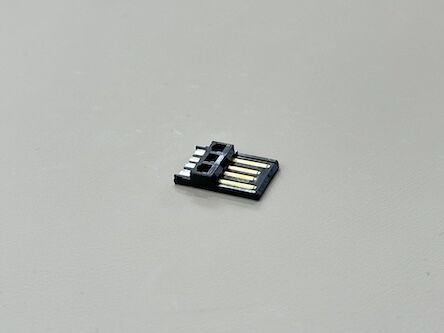

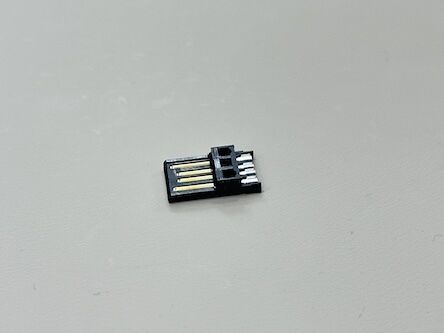

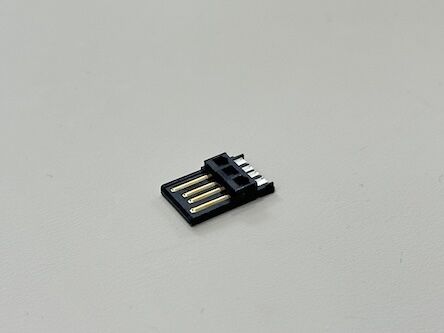

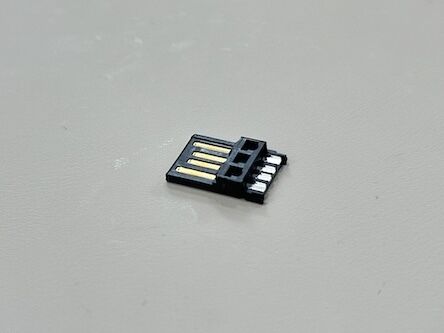

This USB 2.0 AM Male Solder Connector features a widened solder cup at Pin 1 and Pin 4, providing enhanced soldering stability and supporting high-strength wire termination. The 15U” black gold-plated contacts ensure excellent conductivity, low signal loss, and long-term corrosion resistance.

Designed with high-temperature insulating materials and precision-formed terminals, the connector offers reliable performance in data transmission, power delivery, and electronic interface applications. With durability rated up to 5000 mating cycles, it is suitable for professional wiring, custom harness assembly, and high-reliability environments.

The connector supports customization for wire type, cable diameter, plating thickness, and housing color, making it ideal for diversified industrial and commercial requirements.

| Product Type |

USB 2.0 AM Male Solder Connector |

| Assembly Style |

Solder-type with widened solder cup (P1 & P4) |

| Plating |

Black gold-plated 15U” over contact areas |

| Terminal Material |

Copper alloy |

| Insulator Material |

High-temperature engineering plastic |

| Current Rating |

3A Max |

| Voltage Rating |

250V AC |

| Contact Resistance |

≤30mΩ Max |

| Insulation Resistance |

≥500MΩ (500VDC) |

| Withstand Voltage |

500VAC / minute |

| Durability |

≥5000 mating cycles |

| Wire Compatibility |

Suitable for multiple wire gauges depending on design |

| Operating Temperature |

−20°C to +85°C |

| Compliance |

RoHS2.0 + HF |

| Application |

Wire-to-device connection |

Applications

Consumer electronics (USB extension, data cable manufacturing)

Automotive wiring harness and vehicle diagnostic interfaces

Power supply and charging devices

Industrial control equipment and embedded devices

Servers and communication equipment requiring stable signal channels

Customized cable assemblies for OEM/ODM projects

Precautions

Ensure proper soldering temperature to avoid damaging insulation materials.

Verify wire gauge compatibility before assembly to ensure secure soldering.

Avoid bending the solder cup area repeatedly to maintain structural integrity.

Keep contact surfaces clean to ensure optimal conductivity.

Store in a dry environment to prevent oxidation prior to assembly.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!